The use of hydrogen as a fuel in internal combustion engines offers significant advantages over the use of hydrogen in fuel cells. A new research project at Turku University of Applied Sciences aims to overcome the technical challenges that currently prevent the efficient use of hydrogen in internal combustion engines.

Published:

Edited:

Internal combustion engines are material-efficient, i.e. they do not require precious metals or rare earths, which makes them more cost-effective to manufacture and less dependent on limited resources.

There is a large production capacity for internal combustion engines in the EU, allowing a faster transition without major investments in new production facilities. A faster transition to hydrogen would effectively reduce CO2 emissions and thus contribute to climate change mitigation.

The specific combustion properties and material problems of hydrogen have so far prevented its use in internal combustion engines. Not only is hydrogen highly flammable, but hydrogen embrittlement – a phenomenon in which hydrogen weakens the structure of metals – places demands on the materials used.

3D printing is being used to find solutions to these challenges. Printing technology enables rapid component manufacturing, structural modification and optimisation of materials against hydrogen embrittlement.

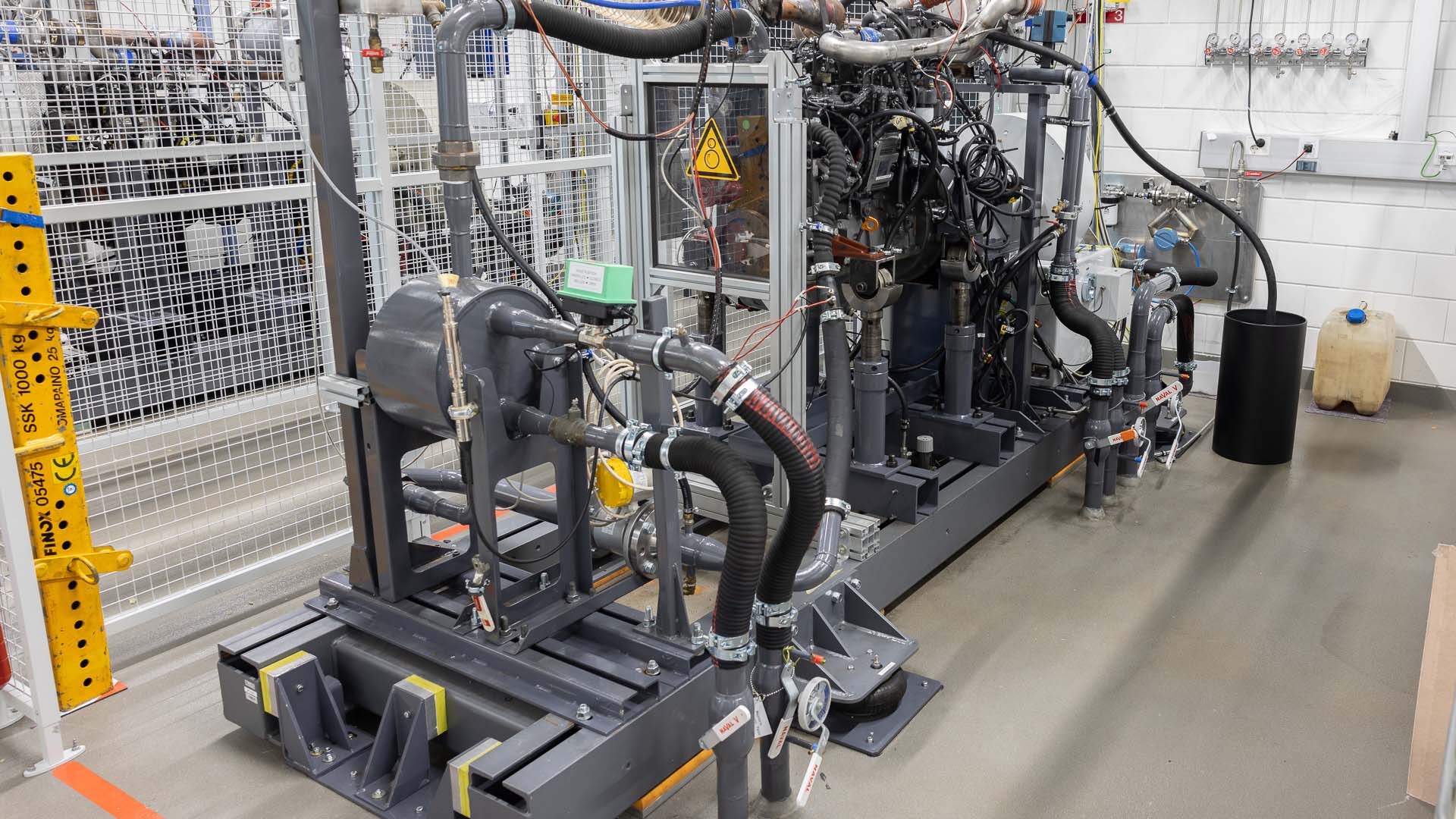

The 3D Hydrogen Engines project at Turku University of Applied Sciences is investigating what the engine structure should be like and what materials should be used in its different parts in order to use hydrogen safely and efficiently.

Towards carbon neutral transport

The project also aims to explore how existing internal combustion engines could be converted to hydrogen or hybrid (hydrogen + diesel/methane/alcohol). This would allow a faster transition towards carbon neutral transport without having to replace the entire car fleet. As a solution, retro-fit installations are being explored to retrofit existing petrol and diesel engines to run on hydrogen.

The 3DHydrogen Engines project is developing a hydrogen internal combustion engine technology that can play a crucial role in the transition away from fossil fuels. The project will use 3D metal printing to develop engine structures and address the challenges of hydrogen decomposition. The aim is to create a functional hydrogen engine suitable for both transport and distributed energy production.

Turku University of Applied Sciences supports RDI work related to the hydrogen economy in the region and enables and implements local demonstration projects. The University of Applied Sciences has been working for more than 20 years on research into engines and fuels and has a modern research infrastructure to implement the project.

“We want to be part of the solution to the energy crisis,” says lecturer Mika Laurén from Turku University of Applied Sciences.

3DHydrogenEngines and 3DHydrogenEngines – investment is one of the projects in Turku that are implementing ecosystem agreements. Innokaupungit are supporters and drivers of new thinking and accelerators of economic renewal. By working together, they can address the current and future challenges of the global sustainability crisis and the Finnish innovation system. https://www.innokaupungit.fi

The project is co-funded by the European Regional Development Fund (ERDF) through the Uusimaa Regional Council.

More information

Read more

-

Press Release

Turku UAS launches StartLab to make students’ business ideas come true

Turku University of Applied Sciences will offer mentoring for all its students to develop their own business ideas. A StartLab will be established where students can go for…

-

Press Release

Turku AMK develops more equal transport in the Turku region

The international project, led by Turku University of Applied Sciences, promotes more equitable and sustainable urban transport in Finland, Hungary, Greece, Italy, the Czech Republic and France. Transport…

-

Press Release

A wetland in Parainen improves the area’s natural values and water quality

A new water protection reservoir designed by Turku University of Applied Sciences has been completed at Sydänperti in Parainen. The wetland is designed to improve the water quality…