Freeform Injection Molding for Medical Application Manufacturing Piloting and Technology Adoption (FIMPACT)

Duration of the project

Source of funding

European Regional Development Fund (ERDF)

Total funding

311 765 €

The project brings to companies in Southwest Finland a new Freeform Injection Molding (FIM) manufacturing technology that enables the rapid and cost-effective production of complex and personalized products without the limitations of traditional molds. The goal is to accelerate product development, strengthen expertise and open up new business opportunities, especially in medical applications..

How to produce high-quality personalized products cost-effectively and quickly? Currently, many personalized and customized medical applications are still largely manufactured by hand or through production processes that impose limitations on product design and manufacturing. Additionally, complex molds are often required, and modifying them is both expensive and time-consuming. Many small and medium-sized enterprises (SMEs) in Southwest Finland struggle to bring new products to market with competitive product development and production costs.

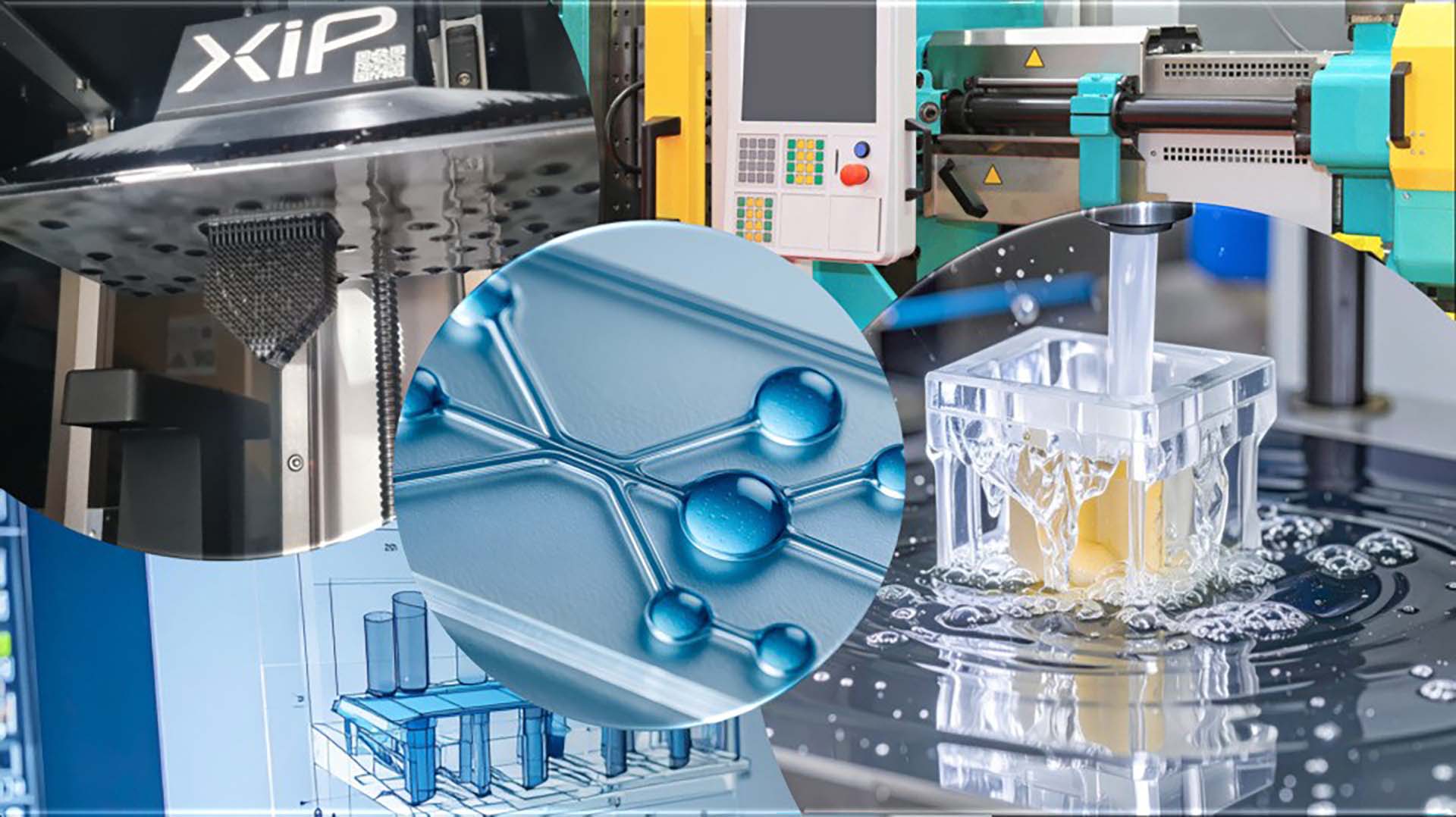

The project pilots a new Freeform Injection Molding (FIM) mold manufacturing technique, enabling the production of freeform components for companies in various fields (in vitro diagnostics, drug delivery, and dentistry). FIM is a manufacturing technique that uses injection molding to create complex and irregular components with dissolvable molds. This technique allows for faster and more cost-effective mold and product manufacturing by overcoming the limitations of traditional mold-making techniques.

Key Cross-Cutting Objectives of the Project:

- Demonstrate the suitability of FIM technology for selected applications by piloting and validating at least three different applications.

- Enhance the expertise of Southwest Finland’s companies in FIM technology and identify suitable use cases for them. Once the feasibility of FIM technology has been demonstrated, the project will explore other potential applications identified by local businesses through interviews and company outreach.

- Disseminate knowledge about the new manufacturing method’s possibilities by organizing workshops and networking events for regional companies.

As a result of the project, FIM technology will be developed to a level where companies in Southwest Finland can utilize it for both product development and actual production. The project will generate new operating models and guidelines for manufacturing selected applications using FIM technology. Additionally, a process comparison will be conducted to evaluate FIM technology against traditional injection mold manufacturing. The comparison will determine how much faster, more precise, and cost-effective FIM-based mold production can be.

The project will test the hypothesis that FIM technology can reduce prototype production time by up to 90% while cutting costs by the same percentage. The mold production time is expected to decrease from eight weeks to a few days, and costs from €10,000 to around €1,000.

Furthermore, the project will measure the material efficiency of injection molding and optimize material utilization. Optimization will reduce the carbon footprint of the injection molding process and improve economic viability. Experimental optimization will demonstrate how efficiently FIM technology utilizes raw materials and generates less waste compared to traditional manufacturing methods. Efficient raw material utilization and waste reduction are particularly relevant to industrial stakeholders.

Demonstrations conducted in collaboration with companies in Southwest Finland will facilitate the practical implementation of this new manufacturing technology. These demonstrations will show that FIM technology can offer innovative solutions to manufacturing challenges faced by companies. They will also support the commercialization potential of FIM technology. This project will introduce the new FIM manufacturing technique to Finnish companies and research groups, enhancing production efficiency and competitiveness in Finland. It will generate new expertise and contribute to the introduction of advanced injection molding technology in the country. In the long term, this will impact traditional product development and production processes as well as the manufacturing capabilities of in vitro diagnostics, drug delivery, and dentistry applications.

Contact us

Meet the research team

-

Research teams

New materials and processes

-

Research teams

Oral Health

-

Research teams

Manufacturing Engineering

See all our projects

We carry out nearly 200 RDI projects annually together with working life and our international partner networks.