Smart brewery

Duration of the project

Source of funding

The Federation of Southwest Finland. Allocation to support sustainable growth and vitality of regions (AKKE)

Total funding

103 260 €

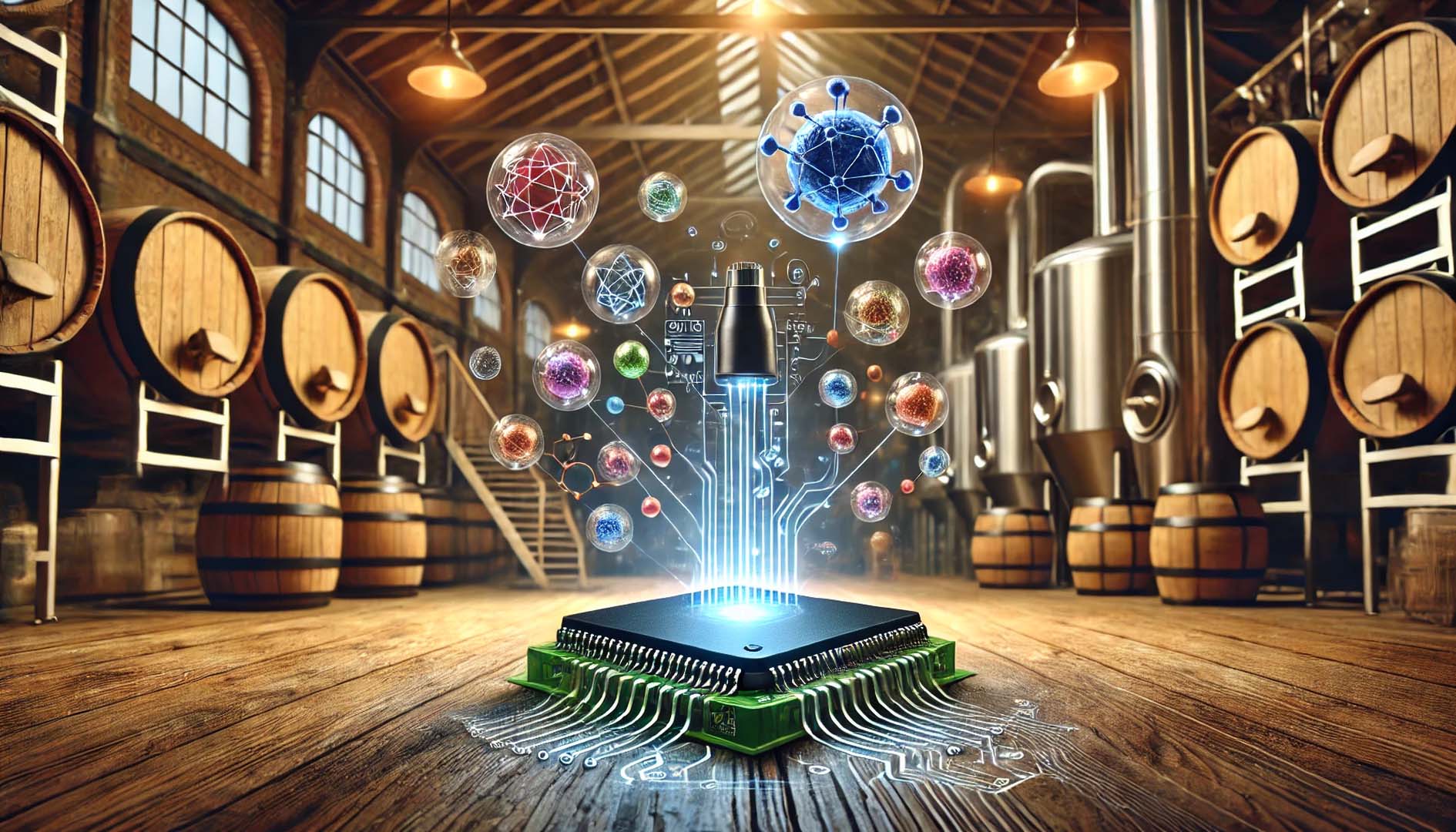

In the brewing process, real-time process measurement and control is essential for energy efficiency and product consistency. In the “Smart Brewery” project, we are focusing on a small-scale pilot to test and develop digitalisation and sensor technology for the brewing process using a variety of methods. The target group of the pilot is in particular small breweries in Southwest Finland.

Readings from existing analogue measuring devices are read out by machine vision technology as digital input to the neural network. In addition, sensors for measuring volatile organic compounds (VOCs) will be installed at different stages of the brewing process. The data collected by the sensors will be combined to train the neural network at the heart of the AI.

The system will initially be piloted at the Kupittaa Campus Brewery of Turku University of Applied Sciences and in the next phase with small breweries in the Southwest Finland region. Our ultimate goal is to offer an open tool for use by all small breweries. Involving the breweries in the project will enable them to develop their technology, use energy more efficiently and achieve a high and consistent quality of production.

The project will increase the competitiveness of small breweries and provide an open neural network solution that can be widely used in the brewing industry. The real-time process control developed by the project will reduce energy consumption in breweries and improve quality control.

Contact us

Meet the research team

-

Research teams

New materials and processes

-

Research teams

Autonomous and Intelligent Systems (AIS)

See all our projects

We carry out nearly 200 RDI projects annually together with working life and our international partner networks.