Turku Protein Core – Data driven optimization of bioproduction

Duration of the project

Source of funding

Business Finland

Total funding

199 946 €

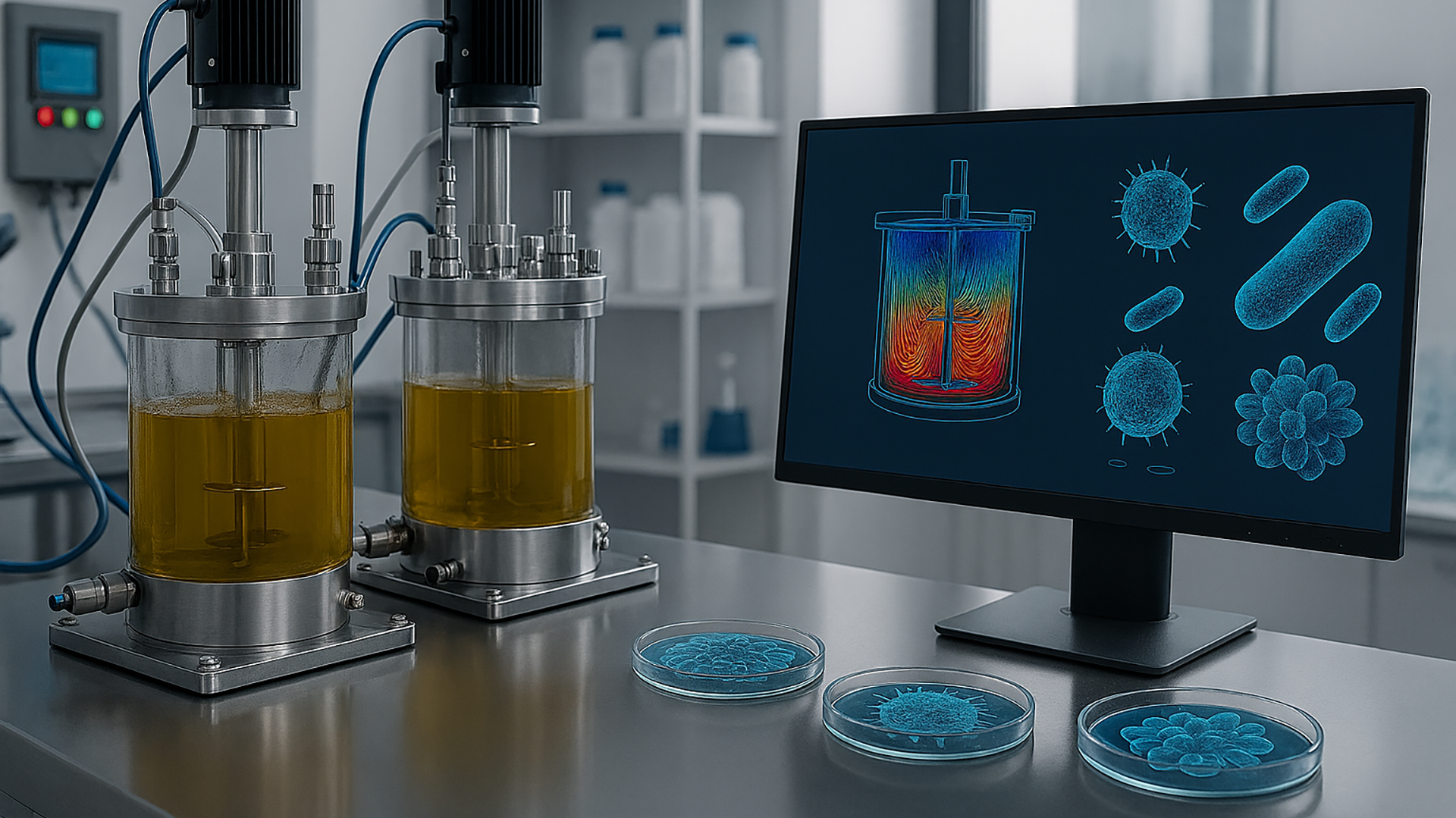

The project focuses on the development of a new generation of small-scale fermentation units for biomedical research and production. By combining real-time digital monitoring, advanced mixing systems and a scalable, modular design, the project will contribute to cost- and energy-efficient bioprocessing.

These solutions will enable SMEs and research institutes to optimise their fermentation processes, accelerate drug development and improve production yields. At the same time, the project will strengthen collaboration between research institutions and SMEs and support a sustainable and digital transition in the biotechnology sector.

Biopharmaceuticals are substances derived from living organisms. They are used to prevent, diagnose, treat or relieve symptoms of a disease. Developing them is a complex process that relies heavily on research and innovation. Small and medium-sized enterprises (SMEs) play a key role in these early discovery stages, often working at the cutting edge of new therapeutic breakthroughs. The road from discovery to production is long. Biopharmaceuticals must be tested, analyzed, and refined through countless experiments — and one of the most critical steps in this journey is fermentation.

Fermentation, a process where microorganisms are cultivated in controlled environments, is the primary method for producing proteins, active pharmaceutical ingredients (APIs), and other natural compounds. Optimizing fermentation conditions is therefore crucial for maximizing yield, yet existing solutions often fall short of an ideal system, in particular for companies with limited resources.

Project aims to revolutionize biopharmaceutical production by developing a smart, modular fermentation platform tailored for small and medium-sized enterprises (SMEs) and research institutions. The focus is on creating compact fermenter units that are scalable, energy-efficient, and digitally optimized to meet the evolving needs of biotechnology applications.

These units are designed to cultivate a wide range of organisms, including Escherichia coli, anaerobic soil bacteria, and eukaryotic cell lines—each critical for producing proteins, active pharmaceutical ingredients (APIs), and modern therapeutics such as antibodies.

A key innovation lies in the integration of real-time digital monitoring systems. These systems continuously track essential fermentation parameters such as temperature, gas composition, and nutrient levels. Combined with predictive mathematical models, they enable precise control and optimization of the fermentation process, transforming it from a manual, empirical approach into a smart, automated, Industry 4.0-compatible system.

Digitalization enhances productivity, consistency, and scalability, especially for SMEs that often operate with limited resources.

The project also introduces a novel rotating mixer blade system, designed using full-scale Computational Fluid Dynamics (CFD) simulations. This system improves aeration and nutrient distribution while minimizing cell damage due to cavitation and shear stress. CFD modeling also supports the development of virtual sensors, further enhancing the digital instrumentation and monitoring capabilities of the fermenters.

These fermenter units are modular and customizable, allowing for rapid prototyping and parallel batch production. Their affordability and flexibility make them ideal for SMEs engaged in early-stage drug discovery and development.

By bridging the gap between academic research and industrial application, Turku Protein Core project delivers a versatile, scalable, and highly automated fermentation platform. It empowers SMEs and research institutions to innovate faster, produce more efficiently, and compete globally in the biopharmaceutical market.

Contact us

Meet the research team

-

Research teams

Computational Engineering and Analysis

See all our projects

We carry out nearly 200 RDI projects annually together with working life and our international partner networks.